Writer: Eric Bearing Limited

FAG Precision Bearings: The Backbone of Modern Machinery

In the ever-evolving world of industrial technology,FAG precision bearings have emerged as a critical component in ensuring the efficiency, reliability, and longevity of modern machinery. These highly engineered components are designed to reduce friction, support heavy loads, and enable smooth rotational motion, making them indispensable in industries ranging from aerospace and automotive to robotics and renewable energy.

What Are FAG Precision Bearings?

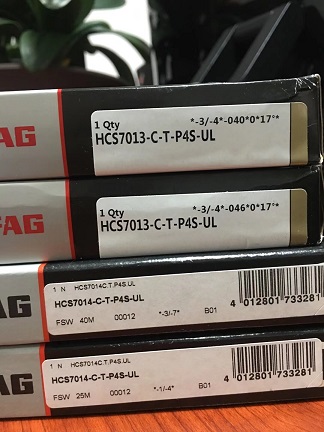

FAG precision bearings are specialized types of bearings manufactured to extremely tight tolerances. for example FAG HCS7013-C-T-P4S-UL & HCS7014-C-T-P4S-UL,Unlike standard bearings, which are designed for general-purpose applications, precision bearings are crafted to meet the exacting demands of high-performance systems. They are typically used in applications where even the slightest deviation can lead to significant performance issues, such as in medical devices, high-speed trains, and precision machining tools.

Key Features and Benefits

High Accuracy: FAG precision bearings are manufactured with minimal dimensional variations, ensuring consistent performance and reducing the risk of mechanical failure.

Low Friction: Advanced materials and lubrication techniques are employed to minimize friction, which in turn reduces energy consumption and heat generation.

Durability: Made from high-quality materials such as ceramic or specially treated steel, precision bearings are designed to withstand extreme conditions, including high temperatures and corrosive environments.

Versatility: These bearings are available in various types, including ball bearings, roller bearings, and needle bearings, each tailored to specific applications.

Applications Across Industries

Aerospace: FAG precision bearings are crucial in aircraft engines and landing gear, where reliability and performance are paramount.

Automotive: In the automotive sector, they are used in transmissions, wheel hubs, and electric vehicle motors to enhance efficiency and reduce emissions.

Robotics: The robotics industry relies on precision bearings for smooth and accurate movement in robotic arms and automated systems.

Renewable Energy: Wind turbines and solar tracking systems use precision bearings to ensure optimal performance and longevity.

Recent Innovations

The precision bearing industry is continually advancing, with recent innovations focusing on smart bearings equipped with sensors to monitor conditions such as temperature, vibration, and load in real-time. These smart bearings can predict maintenance needs, thereby preventing unexpected downtime and extending the lifespan of machinery.

Conclusion

As industries continue to push the boundaries of technology, the demand for precision bearings is expected to grow. Their role in enhancing the performance and reliability of modern machinery cannot be overstated. For businesses looking to stay competitive, investing in high-quality precision bearings is not just an option—it's a necessity.

For more information on the latest advancements in precision bearing technology, stay tuned to our website.

Tel: 00852-30697500

Fax: 00852-30697511

Email: sales@ericbearing.com

Message: Click Here Message!