Repair Experience of Hydrostatic NSK Bearings

Writer: Eric Bearing Limited

The static pressure NSK bearing is characterized by its high rotation accuracy, good rigidity, high bearing capacity, no wear and high durability. The following are some experiences of static pressure NSK bearings explored and tried during the maintenance process, for your reference only.

1. Small hole throttle

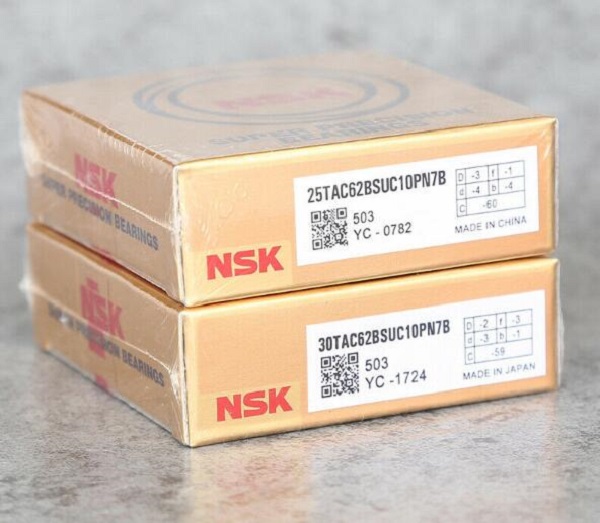

(1) Change the internal throttling to external throttling, and install a pressure gauge to immediately display the pressure in the upper and lower chambers. Make maintenance and repair convenient, especially can be easily cleaned regularly, which is unmatched by the internal throttle. NSK 30TAC62BSUC10PN7B precision bearings are online , pls click here :

(2) Throttle ratio. The theoretical value of the throttle ratio β is between 1.2 and 1.5, and 1.25 is better based on years of experience. In this way, in the maintenance, it is necessary to strictly control the geometric accuracy of the main shaft, the geometric accuracy of the front and rear bearing pads, the coaxiality, roundness and taper, in order to ensure the β value. Determine the value of e (the amount of eccentricity between the main axis and the geometric center of the bearing pad) according to the load-bearing capacity of the machine tool to optimize the value of β.

(3) When the oil chamber is not equipped with a main shaft, the oil column of each oil outlet must be consistent (observation method). If they are not consistent, the method of changing the aperture of the throttle should be adopted to change its flow rate. Taking 4-chamber as an example, the oil column of the lower, left and right chambers is generally between 20 and 25 mm, and the diameter of the small holes is 0.25 and 0.4 mm.

2. Film feedback throttle

The rigidity of the thin-film feedback throttle bearing is very large, but the machine tool often has the phenomenon of holding shoes, brushing, and pressure drop during operation. The most important thing for film feedback is the film. In practice, the main reasons for bearing block and brushing are: ① caused by the plastic deformation of the film;

②Slow feedback. When the load is abruptly changed, and the film has not reacted, the shaft and the tile have rubbed;

③ Film fatigue. The film has a long service life and fatigue deformation, which is equivalent to changing the feedback parameters.

Increasing the thickness of the film and switching to some fatigue-resistant materials can achieve good results.

Generally, rigid membranes, preloading, and gaps are used. The specific method is: change the 1.4mm thick film to a 4mm thick rigid film, and place a 0.05mm thick foil in the lower cavity to adjust the spindle to a position 0.05mm higher than the ideal position. The purpose is to return to the ideal center when the spindle is stressed (wheel weight, cutting force).

3. Improvement of oil supply system:

In the static pressure NSK bearing oil supply system, in addition to coarse filtration and fine filtration, the remaining components have a protective effect on the static pressure bearing. Improve the oil supply system on the basis of the original system.

(1) Connect the pressure relay and pressure gauge (originally in front of the accumulator) to the oil outlet behind the throttle plate, so that the operator can see the size of the chamber pressure and NSK pressure. When the pressure difference is greater than a certain value, in order to stop immediately, so as not to lock the bearing. Such as: NSK pressure 2MPa, outlet pressure 1.2 ~ 1.6MPa, below 1.2MPa will shut down.

(2) Add digital detection device

There is a gap of 0.04~0.05mm between the main shaft of the static pressure NSK bearing and the bearing bush, and the oil between them has a certain resistance value. By detecting the change of this resistance value, you can know the size of the period gap. With the main shaft as one pole and the bearing pad as the other pole, the change in resistance is measured. This signal is processed and sent to the photoelectric alarm and the control system amplifier to control the start and stop of the spindle motor, so as to avoid the friction between the shaft and the tile.

NSK bearing speed limit index

Generally, the index of speed limit is included in the NSK bearing model table. What does it mean?

When the NSK bearing exceeds a certain operating speed, it will begin to generate uncontrollable internal heat.

The speed limit varies with NSK bearing type, size, lubrication system, NSK bearing internal design and working load. In addition, the speed limit will vary depending on the type of synthetic NSK bearing seal used (depending on the speed of the seal contact area).

The term "speed limit" generally refers to the estimated speed, revolutions per minute, at which the NSK bearing will remain available.

The general speed table will give the limit speed of grease lubrication and oil lubrication. This value is based on NSK bearings installed on a horizontal shaft, suitable for lubrication operation, and light load.